Damascus

Damascus knife gives off a mystique from its own elegant pattern, toughness, and durability.

Please imagine that your kitchen knives have more aesthetic appeal as well as sharpness and durability, they're sure to get an additional value for excellent gift, collection and cooking before people. Kitchen knives with beautiful DAMASCUS pattern are believed at the forefront in the world.

Check all items of Damascus Knives >

The followings are picked up for those who are looking for the damascus kitchen chef knives.

Recommended Damascus Blades

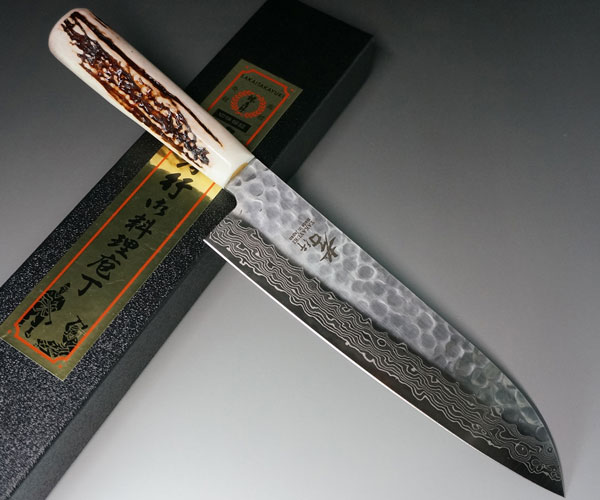

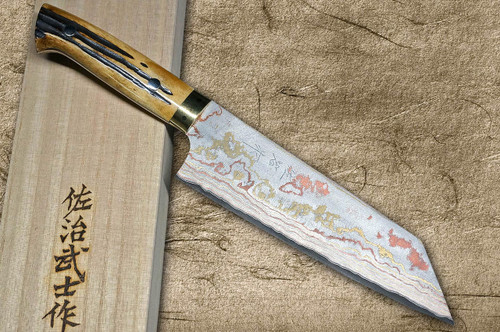

(1) Damascus Hammered Texture

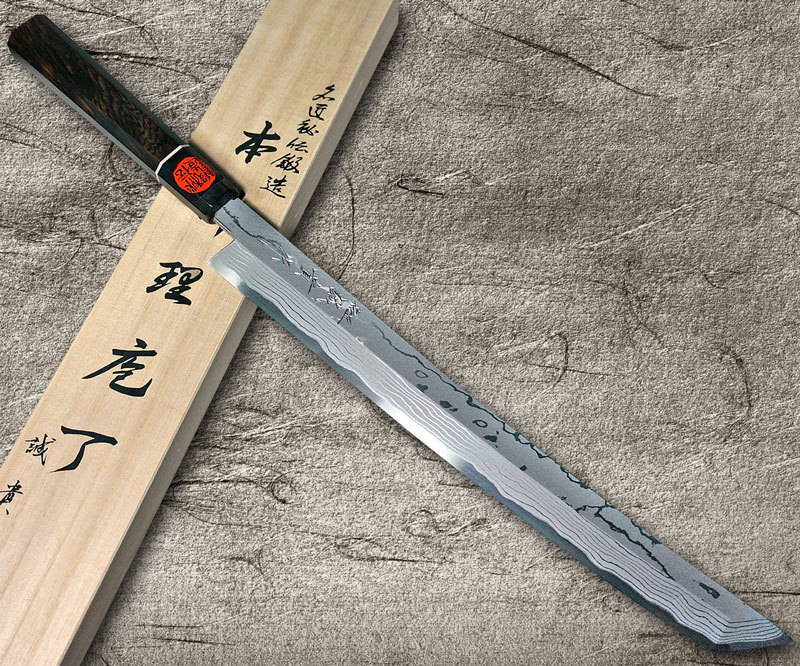

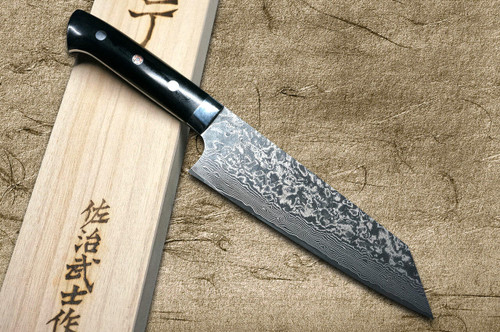

(2) High-Density Damascus

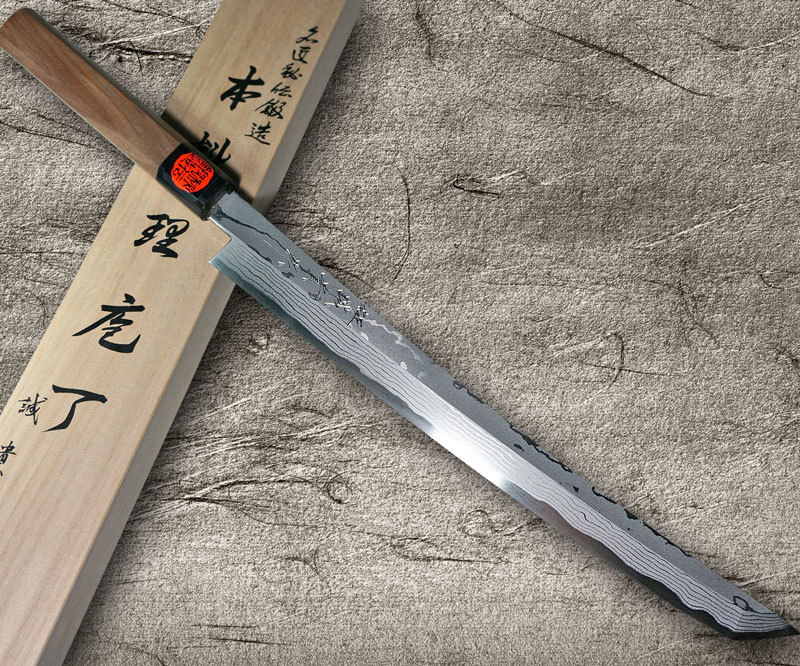

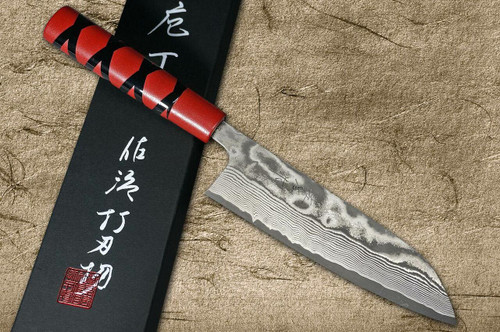

(3) Japanese Traditional Style Blade Damascus

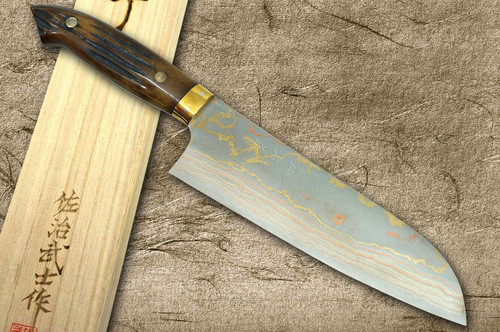

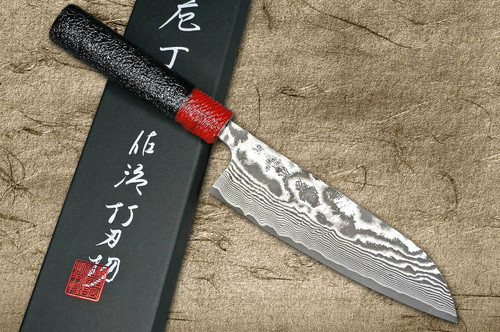

(4) Damascus & Stylish Feature

Mysterious History of Damascus Knives

(1) Outline

Damascus steel was said first developed and used in Ancient South India and the Indian steelmaking technology was superior and was spread to Middle East. And the steel was highly esteemed and the blade was passed down by dynastic hidden treasure. But today, the original method of producing Damascus steel is not known or lost. Despite this, beautiful Damascus texture has successfully been reproduced by using the latest forging technology, process and materials that might be different from the Indian original one.

Especially Japan has developed its own excellent manufacturing method in forging of Katana (or Swords) and Kitchen knives (or Sushi knives), and it was successfully applied to the extraordinary sharp and beautiful Damascus blades. Therefore we’d be more than happy to introduce these Damascus knives made in Japan.

(2) Mysterious History in India

“Damascus”, also known as “Wootz”, is the name of steel material with a wooden pattern and is thought to have originated from the Ancient India. It’s also perceived as one of the materials used to make a strong sword. As much of its manufacturing method haven’t been uncovered completely, it is sometimes associated with something legendary or mysterious.

Close-up of an 18th-century Persian-forged Damascus steel sword[1]

(3) When did Damascus steel appeared for the first time?

There is a huge iron pillar called “iron pillar of Delhi” in India, which is allegedly made of Damascus steel. It is believed to have been established in third or fourth century B.C. Based on this, it should be correct to assume that Damascus steel itself had begun to appear earlier than that period. This Damascus steel had been famous for its unique and distinct pattern appeared on its surface and rust-proof nature.

A scientific research carried out on the “iron pillar of Delhi” unveiled a surprising fact – it is made of forging steel! (not alloy steel).

Iron pillar of Delhi [2]

The Indian steel manufacturing method has been appreciated since a very long time ago. Round chisels made of steel and another steel objects were unearthed in the old graves close to Wurre Gaon in Kamptee, which is thought to have been made around 1500 B.C (some estimate around 600 B.C). It means that these steel objects had already been manufactured a couple of centuries before the period when “iron pillar of Delhi” was established.

“Damascus steel” was known as appropriate for a blade not for a pillar. The following are examples often cited to signify quality and sharpness of Damascus blade: “If a silk scarf drops on a Damascus blade with its edge up, the scarf will be cut into two pieces in a second due only to its weight.” “Damascus blades are never chipped even if they are used to cut iron armor.” “It’s so resilient as if it were a willow branch. It won’t break even if it’s bended. It takes only a second for it to go back to its original state – release a blade, and you will notice that it immediately goes back to the same as it was again.”

All of them sounds a bit exaggerated but describe exactly what “Damascus steel” is all about. Not only its quality as blade but also its mystery - its strength, unique pattern on its surface and rust-proof property- are the main reasons to make the above examples sound plausible.

In the Crusader period, Damascus swords attained an unparalleled reputation and had been passed down as an heirloom of royal families. Also, the Crusaders were proud of having a Damascus sword. The recent study found that the secret to a sharp, rust-proof and resilient feature of Damascus blade lies in the manufacturing process where its specific pattern is formed.

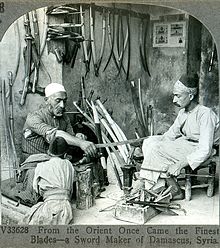

A bladesmith from Damascus[3]

Damascus steel were so famous that was often exported to neighboring countries from India whereas its manufacturing method had not been communicated at all. It is said that the manufacturing method was only passed down from father to son, therefore, there was only a limited number of people well versed in making the steel. Before long, guns appeared and gradually took the place of Damascus steel. The manufacturing method of Damascus steel came to an end 200 years ago, which makes it extremely hard for us now to reproduce the method entirely.

(4) Damascus kitchen knives in the current era

“Damascus steel” currently used for a high-end hocho knife is laminate material, which is forged with multi-layered different steels and has a similar pattern to the one surfaced when Wootz steel is forged. Currently, layered materials with hard core material inserted in-between are forged and ground to make a Damascus knife. In its structure, hard and fragile core material is surrounded and protected by sticky and hard-to-tarnished layered materials, which makes Damascus knife not only very sharp, durable and rust proof but also look beautiful in design.

For this reason, manufacturing a knife with a beautiful Damascus pattern has become very popular recently. In addition to that, Japonesque design, historical sword manufacturing technology and Japanese traditional craftmanship has added intriguing flavor to a Damascus knife and made it all the more popular around the world.

References

[1],[3] Wikipedia : Damascus steel

[2] Wikipedia : Iron pillar of Delhi